Custom Logo and Mold Development: What Buyers Should Know About MOQ, Tooling Fees, and Production Timelines

Essential Planning for Private-Label Sustainable Tableware Production

With the rapid expansion of sustainable food packaging, distributors and private-label brands increasingly request customized tableware—whether branded embossing, unique shapes, or fully original designs. This article explains the essential considerations for buyers planning custom production, including MOQ requirements, tooling fees, and realistic lead times.

1. Minimum Order Quantity (MOQ) Requirements

Understanding MOQ requirements is the first step in planning a successful custom tableware project.

Standard Logo Embossing

For standard logo embossing, most factories set a minimum order quantity (MOQ) of 50,000 units per item. This volume allows factories to balance production efficiency with tooling costs. Buyers working with retail chains, supermarkets, or restaurant groups often find this MOQ manageable, while smaller importers may prefer stocking standard items.

New Mold Development

When the customization requires a completely new mold—common for branded clamshells, trays, plates, or cup lids—the MOQ is typically higher to amortize the significant tooling investment. For a new custom shape, the MOQ usually starts at 150,000 units per SKU.

2. Tooling Fees and Investment Structure

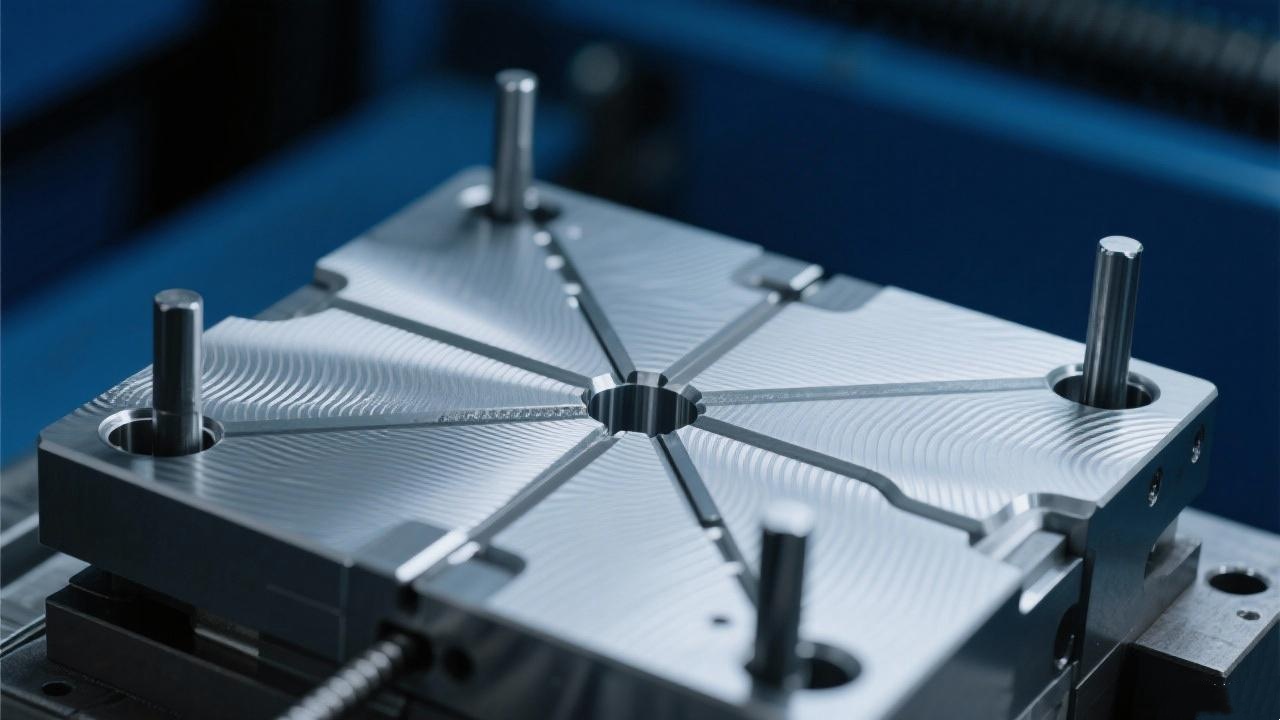

Custom mold development requires significant upfront investment in precision tooling that can withstand high-pressure production cycles.

| Tooling Type | Typical Cost Range | Purpose & Characteristics |

|---|---|---|

| Sample/Prototype Mold | ~ USD 1,000 | Used for initial prototype testing and design validation. Lower durability, suitable for limited production runs. |

| Mass-Production Mold | USD 5,000 -10,000 | High-precision steel mold designed to withstand 500,000+ production cycles. Maintains dimensional accuracy across large volumes. |

These fees are industry-standard because molds must withstand high-pressure wet-pressing cycles and maintain dimensional accuracy across tens of thousands of units. The investment in quality tooling ensures consistent product quality and reduces long-term production issues.

3. Production Timeline: From Concept to Delivery

Production lead time follows three clear stages, each with its own timeline and quality checkpoints.

| Production Phase | Duration | Key Activities & Deliverables |

|---|---|---|

| Prototype Development | 10-15 days | Initial design, sample mold creation, prototype testing for stiffness, heat resistance, and lid compatibility. |

| Full Mold Production | 20-30 days | Manufacturing of high-precision production mold, quality verification, and initial test runs. |

| Mass Production | 25-40 days | Full-scale production run, quality control checks, packaging, and preparation for shipment. |

Prototype creation generally requires 10-15 days, during which samples are tested for stiffness, heat resistance, and fit with corresponding lids or cutlery. Once approved, full mold production takes 20-30 days. After mold completion, mass production typically needs 25-40 days depending on order quantity and factory capacity.

4. Logistics and Quality Consistency Considerations

Beyond production, several logistical and quality factors significantly impact the success of custom tableware projects.

Shipping and Container Loading

Buyers often ask whether mixed-container shipping is allowed. Reputable factories can mix containers with bagasse, cornstarch, and cutlery items, but for custom items with large volumes, full-container loading is more cost-efficient. This also shortens lead times because production can run continuously without waiting for other SKUs.

Quality Consistency Standards

Custom-branded products must meet strict repeatability standards so every item appears identical on store shelves. Professional factories maintain tolerance controls such as:

- Dimensional Accuracy: ±1.5 mm tolerance across all dimensions

- Weight Consistency: ±3% weight deviation between units

- Color Uniformity: Consistent color matching across production batches

- Periodic Mold Adjustment: Regular maintenance to ensure ongoing quality consistency

For buyers supplying e-commerce retailers, this consistency is essential for reducing customer returns and maintaining brand reputation. Professional factories implement strict quality control protocols throughout the production process to ensure every unit meets specifications.

5. Strategic Planning for Custom Tableware Success

To summarize, custom eco-tableware development requires careful planning around MOQ, mold cost, and realistic timelines. A structured approach helps buyers avoid delays and ensures the final product meets both functional and branding requirements.

Successful custom tableware projects begin with clear communication of requirements, realistic expectations about costs and timelines, and partnership with a manufacturer that has proven experience in custom sustainable packaging. By understanding these key factors—MOQ requirements, tooling investment, production lead times, and quality standards—buyers can make informed decisions that balance brand differentiation with practical business considerations.

Whether you're launching a new private-label brand or expanding an existing product line with custom designs, working with an experienced manufacturer who can guide you through each stage of the process is essential for achieving optimal results within your budget and timeline constraints.